Experiment No. 9:

Standard test method for the determination of the splitting tensile strength of cylindrical concrete specimen. (ASTM C 496/C 496 M-04)

scope & significance:

This test method is used for the determination of splitting tensile strength of cylindrical concrete specimen.Splitting tensile strength is helpful for the following purposes;

- Splitting tensile strength is generally greater than the direct tensile strength and lower than the flexural strength (modulus of rupture).

- Splitting tensile strength is used in the design of structural light weight concrete members to evaluate the shear resistance provided by concrete and to determine the development length of the reinforcement.

T=2P/(ld)

where, T = Splitting tensile strength (to be reported in 0.05 MPa multiples)

P = Applied load l = length of the specimen (mm) d = Diameter of the specimen (mm)

Apparatus:

- Testing Machine

- Supplementary Bearing Bar Or Plates (If the diameter or the largest dimension of the upper bearing face or the lower bearing block is less than the length of the cylinder to be tested, a supplementary bearing bar or plate of machined steel shall be used. The bar or plate shall be manner that the load will be applied over the specimen.)

- Bearing Strips (Two bearing strips of nominal 1 /8 in [3.2 mm] thick plywood, free of imperfections, approximately 1 in. [25 mm] wide, and of a length equal to, or slightly longer than, that of the specimen shall be provided for each specimen. The bearing strips shall be placed between the specimen and both the upper and lower bearing blocks of the testing machine or between the specimen and supplemental bars or plates, when used

Size Of The Specimen

The specimen is a cylinder of 150mm diameter and 300mm height. Determine the diameter to the nearest 0.25mm by averaging the three diameters. Determine the length to the nearest 2mm by averaging at least two lengths. Splitting Tensile Strength

Size Of Bearing Strips

According to ASTM specifications, the bearing strips should be 3.2mm thick and 25mm wide. There is no restriction on their length. Splitting Tensile Strength

Rate Of Loading

The rate of loading should be such that a stress of 0.7 – 1.4 MPa/min is produced.

Procedure:

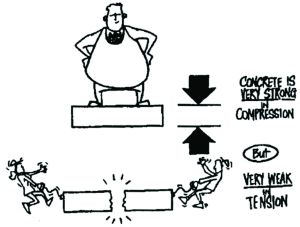

This test method consists of applying a diametrical force along the length of a cylindrical concrete at a rate that is within a prescribed range until failure. This loading induces tensile stresses on the plane containing the applied load and relatively high compressive stresses in the area immediately around the applied load. Although we are applying a compressive load but due to Poisson’s effect, tension is produced and the specimen fails in tension. Tensile failure occurs rather than compressive failure because the areas of load application are in a state of triaxial  compression, thereby allowing them to withstand much higher compressive stresses than would be indicated by a uniaxial compressive strength test result. Thin, plywood bearing strips are used to distribute the load applied along the length of the cylinder.The maximum load sustained by the specimen is divided by appropriate geometrical factors to obtain the splitting tensile strength. Splitting Tensile Strength

compression, thereby allowing them to withstand much higher compressive stresses than would be indicated by a uniaxial compressive strength test result. Thin, plywood bearing strips are used to distribute the load applied along the length of the cylinder.The maximum load sustained by the specimen is divided by appropriate geometrical factors to obtain the splitting tensile strength. Splitting Tensile Strength

Calculations

Calculate the splitting tensile strength of the specimen as T=2P/(ld)

where: T = splitting tensile strength, (psi or MPa),

P = maximum applied load indicated by the testing machine, (lbf or N),

d = diameter, (in. or mm)l = length, (in. or mm), and

|

Sr # |

Maximum Applied Load |

Diameter of Specimen |

Length of specimen |

Splitting Tensile Strength |

|

|

Tons |

N |

mm |

mm |

Mpa |

|

|

1 |

13.5 |

132435 |

150 |

300 |

1.874 |

|

2 |

18 |

176580 |

150 |

300 |

2.498 |

|

Avg |

15.75 |

154508 |

150 |

300 |

2.186 |

Comments:

Splitting Tensile Strength. The Split tensile test performed on the cylinder have shown the same value Tensile value as compared to the tensile value obtained from compressive test experiment. There is some difference in both the values but that difference is very small. The Comparison of both these values has been shown under. Splitting Tensile Strength

|

Compressive strength |

Tensile Strength |

Splitting Tensile Strength |

Percentage difference |

|

37.19 |

2.44 |

2.498 |

2.32 |

|

31.08 |

2.23 |

1.874 |

15.96 |

Am greatful

Thanks

Thanks for sharing informative post.

welcome

sir pie term in denominator is missing, its (2p/Pie x L X D)

I APPRECIATE THE WORK. very good

OK